Harris, Reed & Seiferth

|

|

Out of sight, out of mind! It's a saying that's too often true about making repairs around the base of your home. Problems with manufactured home skirting are common, but thankfully, replacing your mobile home's skirting is easier than you might think.

0 Comments

Do you remember when you were young and had to check under your bed for monsters before you could go to sleep? I sure do! Because of my hyperactive imagination and the poor decision to watch one too many cheesy 80s horror movies, I was absolutely terrified of monsters when I was a kid. Every night I would thoroughly inspect all of the best hiding places in my room before I reluctantly switched off the light and frantically dashed for my bed, fully expecting to be ambushed by a mob of gremlins as soon as everything was dark. I certainly didn't want any mischievous little critters to snack on one of my exposed limbs as I slept, so I wrapped myself in a cocoon of blankets as an extra precaution.

Now that I am an adult who is fairly confident that there are no monsters under my bed, I have a more important question to ask: What's lurking below your mobile home? The answer probably isn't monsters, but here are three things that you may find: Animals Mice, raccoons, squirrels, skunks, insects and other critters may invade the space below your mobile home and cause messes, loud noises, bothersome odors and other damages. Keeping your trash and recycle bins tightly closed and making a point to keep the underside of your home clean of trash and debris are good strategies for keeping otherwise curious animals away. It also helps to keep bird feeders a good distance from your home, as they attract pesky squirrels and raccoons. According to SFGate, sprinkling chili or habanero flakes in the dirt around your home is an effective way to repel many animals. But if you do end up finding an animal under your home, don't try to remove it yourself. Instead, call your local animal control service−they can help you find a safe solution. Water If there is an abundance of clay in the soil around your home or if your yard is not graded well, any water that collects under your home may not be able to drain properly. Rainfall and even plumbing leaks can lead to excess moisture, and if you don't act quickly to fix this problem, your home could become musty and moldy. My Mobile Home Makeover suggests addressing the issue of pooling rain water by stapling plastic sheeting to the bottom frames of skirting so that any water that collects will be absorbed beneath the plastic and will not damage the bottom of your home. You can also install gutters to prevent rain water from pooling underneath or around your home. Holes It never hurts to thoroughly inspect the bottom of your mobile home for holes. Gaps, tears and open spaces enable animals to sneak in and make your home their own. Holes could also expose water pipes and wires, which could easily be damaged by outside elements. If you find holes in the polyethylene belly wrap below your home, SFGate suggests stuffing fiberglass insulation into the space before patching it. Additionally, cleaning the area around the hole will make the patch stick more effectively. Lastly, if you plan to file a claim with your insurance company, be sure to take photos of the holes and other damages and keep careful records of your receipts and invoices related to any mobile home underbelly repairing projects. Routinely checking under your mobile home for animals, water and holes will help you stay aware of potentially monstrous damages that require your attention. An ounce of prevention saves a ton of trouble when it comes to making your home more comfortable. Why put up with drafts, leaks, excess moisture, mildew or pesky pests when you don't have to? You can put a stop to costly drafts or leaks before they start with the right sealant, caulking compound or roof coating. Unwanted moisture can be a problem even in today's well-built and insulated manufactured homes, but not if you take steps to control it. Pests inside or under your manufactured home can also cause trouble. Homeowners agree it's far easier to keep bugs or unwanted animals from getting into their manufactured home than it is to get rid of them once they've moved in! Here are some quick preventive maintenance tips that pay off in both time and money. How to keep out drafts and leaks Sealants, caulking compounds and roof coatings prevent leaks and drafts. Sealing your home is probably the easiest and least costly way to make your home more comfortable and energy efficient. Basically, any crevice, crack or connection (except the edges of siding panels) should be sealed. To determine if your old caulk needs replacing, poke it with a screwdriver or nail. It should have a rubbery consistency. If it is hard, brittle and cracked, remove and replace it as part of your regular preventive maintenance. You will probably need more than one type of sealant to do your entire home. Here are some common sealant types:

Source: https://www.foremost.com/learning-center/mobile-home-repairs-draft-and-leaks.asp

you'd like. Things to consider are the window's location, whether you want a smaller or larger replacement, and the way the original window was mounted on your home. Don't assume that you must replace your old window with an exact duplicate. Many new energy-efficient windows, in a variety of styles, are made for manufactured homes.

Before you go shopping, determine the size of your existing window and check if the window is flush-mounted or mounted for lap siding. A flush-mounted window frame screws on over the siding. If the window has a lap-siding mount, the siding covers the window frame screws. Your new window should have the same type of mount as your current window, for appearance and ease of installation. Before you order a new window, you may want to remove your old window and check that the opening is square. To do that, remove your window, and measure the opening diagonals corner to corner or use a framing square to measure the opening. If the window opening is slightly off-square, you can use shims to fit in a new window. If the opening is significantly off-square, you can reduce the window opening by roughing a new, square frame for a smaller window or you can enlarge the opening for a larger window. It's usually easier to reduce the opening and install a smaller window. If you are replacing a bedroom window, and it's the only exit from the bedroom to the outside, you probably won't be able to make the opening smaller. Bedroom windows that serve as egress windows in case of fire must meet minimum code requirements. To replace your window, you'll need screws, putty tape, silicone sealant, and a screwdriver and/or replaceable drill with screwhead bits. When you purchase your new window, check with the window supplier about any special tools or screwhead bits you'll need.

The process for installing shingles on mobile homes is exactly the same as site-built homes. However, on site-built homes, two or three layers of shingles are acceptable. On a mobile home, one layer is the limit.

This means, if your shingles need replacing, that's exactly what you need to do – remove and replace them. You can't solve the problem by covering them with a second layer of shingles. The reason is weight. A square of shingles that only covers 100 square feet, weighs about 240 pounds. Your roof might require nine or more squares. Mobile home roof trusses aren't built to handle the weight of a double layer of shingles. Fix-It Tips! If possible, replace your shingles on a hot day when they are more pliable and seal better. Seal minor splits and cracks to shingles with roofing cement. You can also try to cement down curled shingles-but they will probably have to be replaced. When Shingles Wear Out Fiberglass and asphalt shingles are durable, water resistant, roofing materials. Under ideal conditions, some of the higher quality shingles may last 30 years, but that is optimistic. If your shingles have been up for 15 or more years, you might need to re-roof in the not-too-distant future – especially if you live in a snowbelt or high heat area. In addition, shingles on mobile homes with low-slope roofs have a tendency to wear out earlier. On a roof with less pitch, the shingles are more exposed to sun, water and snow. It's important to periodically examine your shingles for damage after you have removed all debris. Check them every spring and fall, and after a hailstorm or high winds. Promptly replace any cracked, curled-up, broken or missing shingles. If you don't, rain water could seep under the sheathing and leak into your sidewalls or ceiling. Examine the roof up close from a ladder. Particularly check the roof ridge and valleys for cracked shingles, and the bottom and side rows for curled back or broken shingles. Replacing a damaged shingle is a relatively easy repair. Here's what you'll need to replace shingles - Materials:

Tools:

Step 1: Cut through sealer strips If installed properly, each shingle should have eight nails holding it in place: four in the middle, about ½ inch above the tab cutouts (these four nails also go through the top of the shingle below), and four along the top (these four nails are pounded through the middle of the shingle above). See the diagram that shows how shingles are installed. To replace one shingle, you need to loosen at least three shingles: the one being replaced and the two shingles on the two rows above the damaged shingle. You will need to cut through the sealer strip (also called “adhesive line”) on these shingles. The sealer strip is a dashed line of asphalt adhesive that runs across the middle of the shingle. To loosen, slide a long knife, putty knife or small crowbar under the damaged shingle. The tool must reach over halfway up the shingle. Slide it along the entire length of the shingle. Repeat this procedure for the shingles on the two rows above the damaged shingle. Step 2: Remove nails along middle of damaged shingle You do not want to crack or split the shingles above or below the damaged shingle. Carefully slide a pry bar under the damaged shingle. You might want to slide a piece of plywood under the pry bar to protect the shingle underneath. Gently pry up the damaged shingle, being careful not to damage the shingles above. You do not need to pry the damaged shingle up very far-just enough to loosen the four middle nails. Remove the pry bar and plywood. Carefully lift up the tabs on the shingle above the damaged shingle. Work the nails (in the middle of the damaged shingle) back and forth with your fingers until you can remove them. Step 3: Repeat procedure on next level Remove the four nails holding down the top of the damaged shingle. Because these nails are also holding down the middle of the shingle just above, you will need to gently pry up this shingle to loosen nails. Carefully slide the pry bar under the shingle just above the damaged shingle. Repeat the previous procedure to loosen nails. You do not need to remove these nails. Loosen them just enough so they no longer go through the damaged shingle. Step 4: Remove shingle Slide out the damaged shingle. Use it to size the replacement shingle (if it is not full width.) Step 5: Replace shingle Make sure the replacement shingle is the same size as the old shingle. If not, use a utility knife to cut to fit. Slide new shingle into place, and set flush with adjacent shingles. It should fit snugly. Step 6: Nail Attach shingle with roofing nails. To prevent leaks, pound nails in already existing holes. If this is not possible, seal the existing nail holes in the shingles with roofing cement. You will probably need to pound in the nails after you have laid all the shingles flat. This means you will have to hit the nails through the shingle immediately above. To prevent damaging the shingles, place a board on top of the shingle and hit the hammer on the board. Step 7: Cement Cover all the nails with roofing cement. Press the upper shingles on top of the cement to seal. You may need to weight it down overnight. Source: https://www.foremost.com/learning-center/staying-on-top-of-shingle-repair.asp

When strong winds blow, manufactured homes need special protection. No matter where you live, you need tie-downs and anchors to keep your manufactured home stable and secure. Before you start the job, you should understand why this wind protection system is necessary, and know the basic requirements for tie-downs and anchors. You also need to become familiar with all the components that make up your anchoring system. It's a good idea to consult with an experienced professional installer or building inspector if you have any questions or doubts about the installation.

Why Mobile Home Tie-Downs?

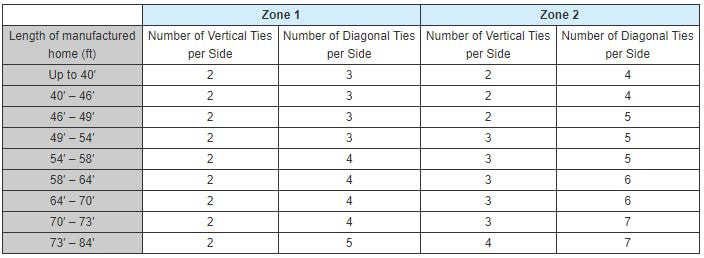

Manufactured homes must have anchors and tie-downs to keep them in place during high winds. Compared to site-built homes, manufactured homes are relatively lightweight. They have flat sides and ends, and they are built on frames rather than foundations. Almost all manufactured homes are elevated, situated on top of some sort of pier or foundation system. Wind can get under the homes and lift them up. In addition, the wind passing over the top of your manufactured home can create an uplift force. To resist wind forces, you need two different types of tie-downs. In older homes, a vertical or over-the-top tie-down is needed to compensate for the uplift force. A diagonal or frame tie-down is needed to compensate for both lateral and uplift forces. Singlewide manufactured homes need both types of tie-downs. Doublewide homes only need the diagonal ties.

Tie Down Requirements For Manufactured Homes

• Singlewide manufactured homes require both diagonal and vertical ties. • Doublewide manufactured homes require only diagonal ties. Length of manufactured home (ft)Number of Vertical Ties per SideNumber of Diagonal Ties per SideNumber of Vertical Ties per SideNumber of Diagonal Ties per Side • To determine the length, do not include the draw bar. • Numbers based on minimum working load per anchor of 3,150 pounds, with a 50% overload of 4,725 pounds. • Diagonal ties must deviate at least 40 degrees from a vertical direction. • If your home has special site considerations, a registered professional engineer or architect can devise an alternate anchoring system. Anchoring System Components

Tie-Down And Anchor Installation

Installing a tie-down and anchoring system is not too complicated for most do-it-yourselfers. It's wise, however, to seek experienced help to make sure you are using the proper anchor for your soil conditions, enough anchors for your wind conditions, the correct tension on your tie-down, and proper angle for your frame tie-downs. At the very least you should have a building inspector or a trained installer check over your finished work.

To make sure you're tied down safely, consult your local building inspector. Looking for Mobile Home insurance? In addition to following the proper steps to tie-down and anchor your mobile home, make sure you have a good mobile home insurance policy in case the unexpected happens. Source: Foremost Insurance - Mobile Home Repair - How to Install Tie Downs And Anchors |

Categories

All

Archives

May 2024

|

Social MediaContact UsNavigation |

|

Website by InsuranceSplash

Privacy Policy | Terms of Use

© 2025 by HARRIS, REED & SEIFERTH INSURANCE GROUP, INC. All rights reserved.

© 2025 by HARRIS, REED & SEIFERTH INSURANCE GROUP, INC. All rights reserved.

RSS Feed

RSS Feed